Abstract

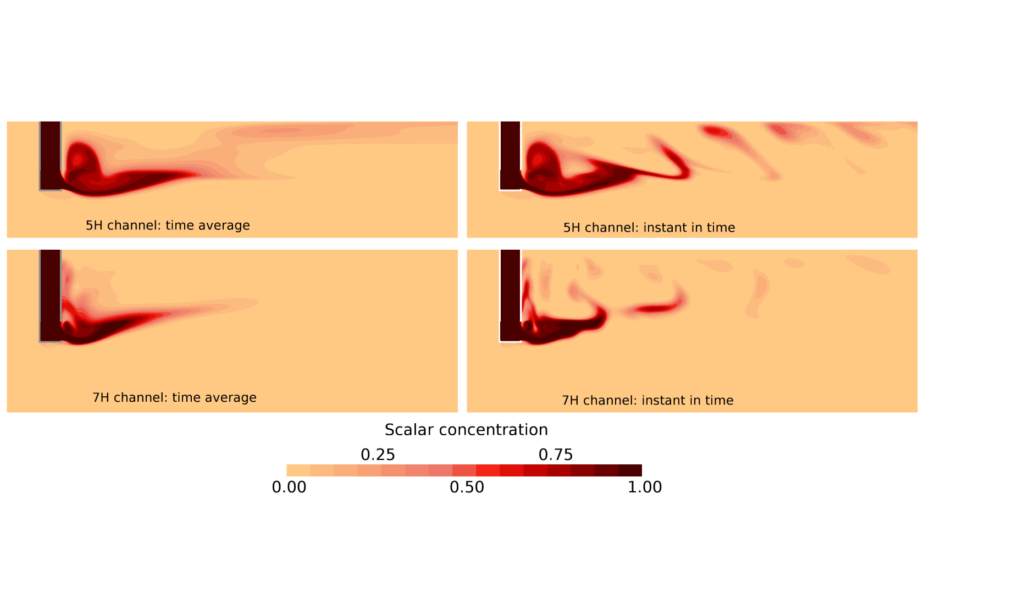

Polymeric flocculants have been used to enhance the settling and thereby the separation process by which the particles mix with the flocculant to produce large porous aggregates which settle quickly compared to the primary particle size. These flocculants exhibit a viscoelastic nature wherein they do not readily with the surrounding slurry at high concentrations typically >0.01% w/w depending on the nature of the flocculant. These flocculants are usually dosed into the thickeners with the aid of a sparge. This paper investigates the mixing nature of high concentration flocculant 0.2% w/w with the aid of different sparge shapes. Two sparge shapes namely round and square which have found widespread use in the industry due to its simplicity are investigated. The outlet for both these sparge shapes are round making them bluff body jets. The effect of oncoming flow while maintaining a constant flow rate through the sparge as well as the sparge orientation were also investigated. The study found at high oncoming flow rates square sparge in general provided better mixing compared to the round at 0o orientation. However, the round sparge seem to show a better mixing characteristic at 180o orientation compared to the square. Lower oncoming flow rate which provided more residence time for mixing in the 180o orientation showed the best mixing behaviour compared to higher flow rate for both the sparge geometries. Across all the conditions investigated the flocculant still preferentially accumulate to the top of the channel geometry due to its viscoelastic behaviour.